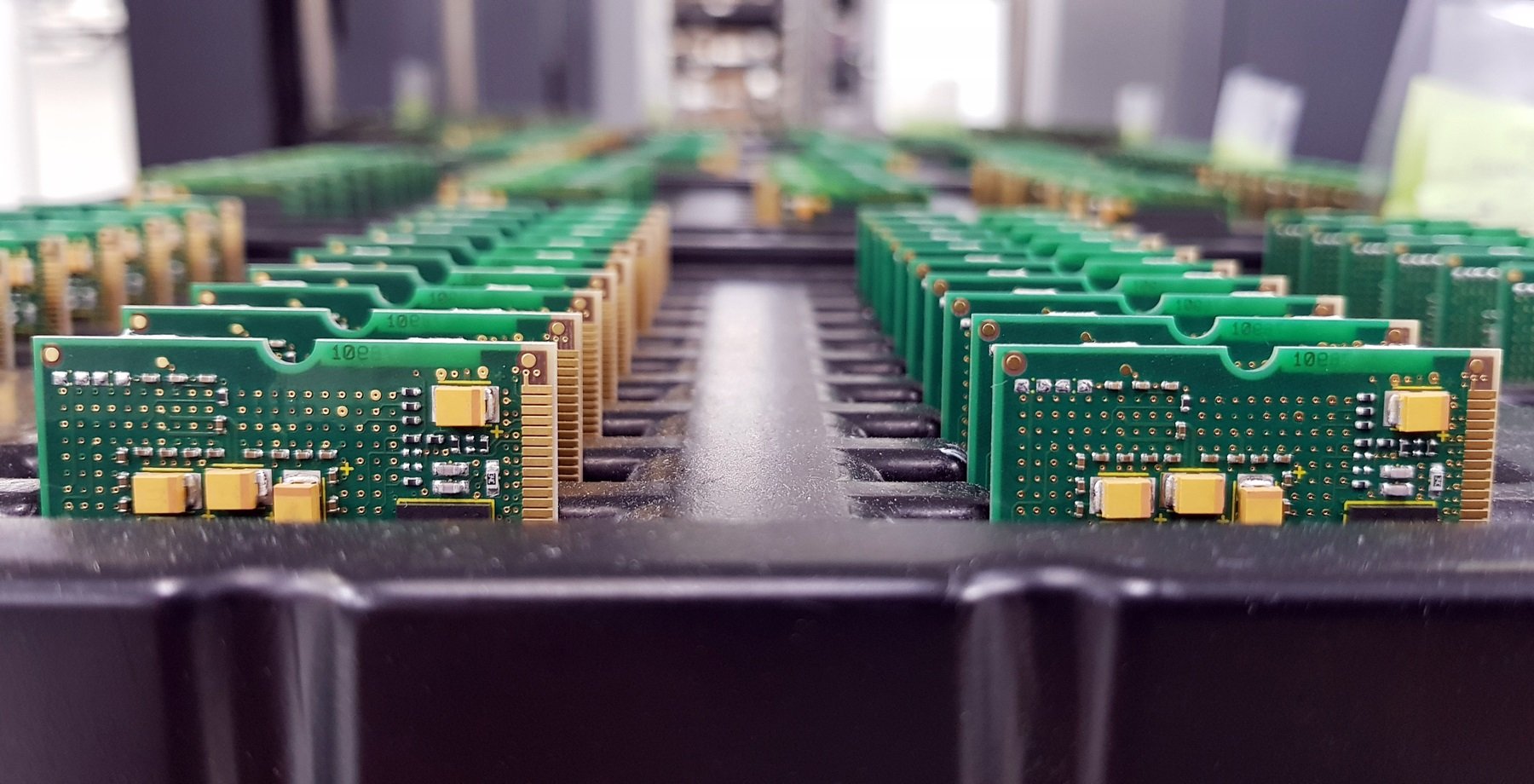

Circuit Board Assembly

Printed Circuit Boards

We provide comprehensive services for the design of printed circuit boards (PCBs) and electronic boards. Whether you need a low volume prototype or a high volume, complex and custom product with embedded systems, we can deliver.

Our services include design and assembly of digital and analogue circuits, software programming, in-house SMT & conventional placement, manufacture and testing. Our knowledge base covers 8, 16 & 32 bit micro control families, including PIC, ST Micro Electronics, Atmel and others. We can work to design concept or full specification briefs - get in touch if you have specialist requirements. Previous product sectors include automotive, agriculture, marine, aerospace, retail, military, energy and more.

Our team can take you from the initial concept and schematic development stage, to prototyping, production, and long-term support and maintenance. With our experience, expertise, and advanced test facilities, we are confident in delivering a successful outcome for your embedded electronics project.

Through Hole Assembly

Our skilled team specializes in hand assembly and hand soldering of components, in addition to offering automated component insertion for both axial and radial components.

Our staff is trained to the IPC 610 standard, ensuring consistent high-quality through-hole PCB assembly. Through-hole jobs require interpretation of the brief, and our attention to detail and careful recording of specific requirements for each assembly allows us to consistently provide high-quality products.

We also offer additional services such as axial or radial insertion, device programming, conformal coating, and complete PCB encapsulation for the final finishing of the product.

Competitive Alternative to Offshore

Now more than ever costs in manufacturing are under pressure. Taking advantage of offshore manufacturing in China can save cost but volumes have to be high and finding the right supplier is difficult. Traction Solutions maintains low overheads and high efficiency to provide a competitive alternative to offshore manufacturing, even at lower volumes.

Surface Mount Assembly

We specialize in all techniques for manufacturing leaded components (PTH or Conventional Assembly). Our expertise in Aerospace, Automotive, IPC, odd form, clinches, press fit, thermal relief, stakings, maskings, and coatings ensures that we can offer you the best manufacturing solution. Our team of professionals is experienced in using HV assembly techniques, critically clean methods, and other measures to ensure the highest quality of your components.

We use automated surface mount assembly techniques to fit electronic components of various sizes, starting from m0402/i01005. Our expert manufacturing practices, combined with full automation and inspection control methods, ensure that the components are fitted perfectly. Our assemblies, not just surface mount, are then manually double-checked to guarantee the best quality for our customers.

In addition, we can produce automated assembly rapid prototypes and FAIR control reports on demand. These manufacturing quality reports can assist with DFM changes and help ensure that your product meets the highest standards.